Integrated protein sciences services for structural biology and biophysics

Our integrated, in-house protein sciences team ensures your proteins have the right modifications, stability, and purity to power confident discoveries. Whether your project involves structural biology, biophysical, or biochemical screening, we tailor expression systems and quality control (QC) processes specifically for your target. This approach minimizes risk of failure and ensures reliable scalability for DMTA cycles and further downstream development.

Why protein science matters

High-quality protein is the foundation of every successful structural biology and biophysics experiment. While off-the-shelf proteins may feel convenient, they often fall short in meeting the standard required for complex targets or targets requiring post-translational modifications, enhanced stability, or tailored assay conditions. Batch-to-batch reproducibility and timely re-supply can also become limiting factors.

Our protein sciences services deliver custom protein production designed to meet the unique needs of your projects. By integrating protein production with your downstream assays, we ensure timely and reproducible access to proteins that are not only pure, but also functional, stable, and precisely aligned with your research objectives.

Key advantages of integrating protein sciences services

Our protein sciences team is not siloed; they work closely with assay development, screening, and structural biology teams to help facilitate end-to-end expertise for every project. When protein production is performed with the big picture in mind, the results are well defined:

- Fit-for-purpose proteins: Designed, expressed, and QC’d for specific assay requirements.

- Reduced risk of failure: Integrated quality control means misfolded or unstable proteins are identified before they derail downstream experiments.

- Seamless transition into assays: Designing the right protein constructs from the start ensures proteins move directly into screening and downstream activities without costly re-optimization.

- Scalability: Protein production strategies are designed with downstream demands in mind, ensuring smooth scale-up for follow-on assays and screening campaigns without the need to restart development.

- Downstream efficiency: By preventing avoidable setbacks caused by mismatched or unsuitable proteins, integrated protein sciences services reduce program whitespace, delays and protein replacement costs.

- Full data ownership: Custom protein production comes with full data ownership and visibility, including ELNs, QC reports, gene sequences, and others.

Core components of custom protein production

Successful protein production isn’t just about expressing a construct. We ensure protein is fit for purpose in downstream structural biology and biophysics applications. Our approach combines rigorous target evaluation, tailored selection of host system, and integrated QC to deliver proteins that support successful screening campaigns.

-

Target evaluation and roadmap design

Every project starts with a thorough assessment of your protein target. Our team has direct experience across many protein families and classes, which means we can quickly anticipate common challenges, whether in solubility, stability, or downstream assay performance. Because we’ve worked on targets at different stages of the discovery pipeline, we understand how production decisions affect workflow and later steps such as crystallography, fragment screening, and medicinal chemistry.

Moving into construct design, our protein sciences team collaborates with structural biologists and assay researchers to review, evaluate and apply all relevant accessible knowledge. Having the right set of constructs early helps avoid unnecessary delays and ensures the proteins you receive are relevant, reliable, and ready for your intended application.

-

Host system selection

Choosing the right host system is critical. We don’t force-fit your project into a single expression system. Our strategy is based on your target’s biology and your downstream requirements.

System Advantages When we recommend it E. coli Fast, cost-effective, easy for isotopic labelling - Ideal for small (simple) protein targets when post-translational modifications aren’t needed.

- Works well with structural biology applications such as NMR and crystallography

Mammalian* Closest to human biology, post-translational modifications - Ideal for large protein complexes, and for maintaining the relevant native protein form

- Works well with functional assays

*By leveraging both systems, we can achieve broader target coverage with higher success rates. The use of a mammalian system helps minimize the longer setup times and higher costs associated with production using insect cells, while also enabling the production of target proteins in a state that closely resembles their native biological form.

When limited information is available about a target, and no clear expression host stands out, we evaluate both hosts in parallel during the feasibility stage. This approach ensures we move forward with the most suitable system for successful protein production.

-

Feasibility

Before scaling up, we conduct feasibility studies to identify the optimal expression and purification strategy. During this phase, we evaluate key variables, such as expression host, different constructs, and expression conditions, to determine the most effective path forward. By narrowing down the many available options in protein expression and purification early, we reduce risk and ensure that time and resources are focused on the most promising path.

Our established feasibility workflows allow us to test multiple variables in parallel, enabling you to reach your first go/no-go decision within 2–3 weeks.

-

Quality control

Unsuitable protein isn’t always obvious until your assay fails, often after months of failed program set-up and troubleshooting. For this reason, we build quality control into every stage of production. This integrated approach ensures that only proteins meeting the required standard and criteria move forward, de-risking downstream studies and preventing costly delays.

QC typically covers:

- Protein identity and purity:

- SDS-PAGE

- Mass Spec verification

- Stability testing:

- Freeze/thaw cycle tolerance

- Thermal melting temperature (Tm) analysis (DSF)

- Functional validation:

- Activity assay (if applicable)

- Binding or interaction confirmation (e.g., SPR, ITC)

- Post-translational modifications (PTMs):

- Glycosylation checks (for mammalian systems)

- Phosphorylation or other relevant modifications

- Aggregation and homogeneity:

- Size exclusion chromatography (SEC) and SEC coupled with multi-angle light scattering (SEC-MALS)

- Dynamic light scattering (DLS)

- Isotopic labeling (if relevant):

- Confirmation of isotope incorporation

- Documentation and traceability:

- ELN records of batch, methods, and results (CDD)

- Gene and plasmid inventory

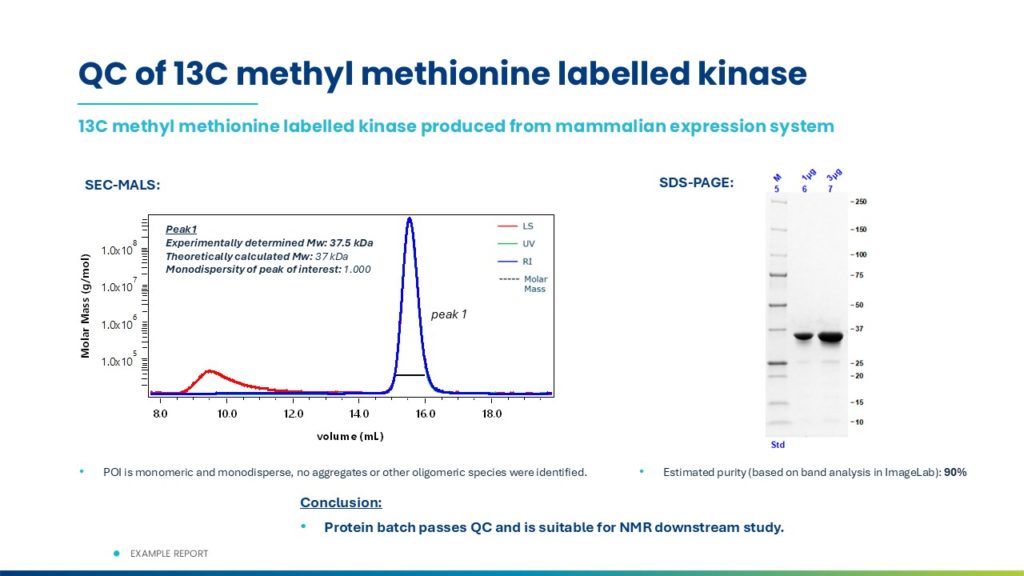

Example QC report:

Above: An example of a protein quality control report. This isotopically-labeled protein was produced in house from mammalian expression system. SDS-PAGE and SEC-MALS are the essential QC checks prior downstream use of a protein, here structural biology (protein-observed NMR).

- Protein identity and purity:

Why not off-the-shelf proteins?

At first glance, buying ready-made protein can seem like the quickest, most cost-effective option. In reality, off-the-shelf proteins often introduce hidden risks that can derail structural biology or biophysics projects. These proteins are not produced with your application in mind, which means they may lack critical modifications, suffer from poor stability, or fail to perform consistently in complex assays.

By choosing custom protein production services as part of an integrated workflow, you gain access to fit-for-purpose proteins that have been designed, QC-tested, and scaled for your specific application. This helps facilitate reliable results, shorter project timelines, and greater confidence at every decision point.

Common challenges when using off-the-shelf proteins:

- Not suitable for purpose: Commercial proteins are rarely optimized for advanced assays such as SPR, NMR, crystallography, cryo-EM, or fragment screening.

- Missing modifications: Complex human proteins often require glycosylation or other post-translational modifications that bacterial expression systems cannot provide.

- Quality gaps: Standard QC from suppliers may not reveal stability, folding, or functional issues that only become apparent once downstream experiments fail.

- False economies: A low upfront price and faster initial sourcing can lead to higher downstream costs when timelines slip, assays must be repeated, or alternative proteins must be sourced.

Our protein sciences services are led by scientists who understand the whole discovery pipeline, not just the upstream science. That means every construct, QC report, and assay setup is designed with your project’s bigger picture in mind, helping to steer your discovery project around potential dead ends and adding confidence to decision-making.

Ready to Get Started? Discuss your target with our experts and see how custom, fit-for-purpose protein production can unlock faster, more reliable results: